The Working Principle of Jaw Crusher - YouTube

Apr 01, 2008 · http://www.limingchina.com This jaw crusher machine uses motor as its power. Through the motors wheels, the eccentric shaft is driven by the …

What is a Jaw Crusher?

What is a Jaw Crusher? From sedimentary rock, granite, and basalts to concrete waste, glass, and other brittle materials, the overhead eccentric jaw crusher is the most widely utilized primary crushing system. A jaw crusher is a compression machine. It consists of 2 corrugated jaw …

Jaw Crusher Working Principle Animation - YouTube

Jan 18, 2019 · Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaws; …

Selecting the Right Crusher for Quarry Operations | Agg-Net

Like the jaw crusher, the cone crusher provides a relatively low-cost crushing solution, but there are application drawbacks which may make another crushing solution more appealing. First, cone crushers cannot accept all material sizes. Any material fed to the crusher must be pre-sized for that particular crusher …

Jaw Crusher for Mining, Construction and Aggregate Industries.

Jaw Crusher s are ideal for various crushing operations and designed for material size reduction, and widely used in mining & metallurgical, construction, road and railway building, and chemistry …

Jaw Crusher | Mining Quarrying and Recycling | Powerscreen

Powerscreen jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying and recycling industries. These machines are amongst the most advanced and …

Jaw Crushers | McLanahan

Jaw Crushers Jaw Crushers are used to reduce the size of many different types of materials in many applications. The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers.

Jaw crushers - liming

Jaw crushers are a popular alternative to primary gyratory crushers, since they can process large amounts of hard material efficiently. For 45 years, liming C Series jaw crushers have proven their reliability in different primary crushing operations in aggregates, mining and recycling applications, with up to 11,000 jaw crusher …

Jaw Crushers - 911Metallurgist

A critical point in the operation of large jaw crushers is the arrangement of swing jaw and its supporting shaft. While in most crushers the jaw is pressed on the shaft and the latter swings in …

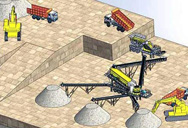

Crushing Plant--Jaw Crusher

The Big materials are fed to the jaw crusher evenly and gradually by vibrating feeder through a hopper for the primary crushing. After first crushing, the material will transferred to impact crusher …

What is a Jaw Crusher? | Telsmith

A jaw crusher is a compression type crusher, comprised of a fixed jaw and moving jaw positioned in a (V). The movable jaw compresses material against the fixed jaw, crushing the material to the …

Jaw Crushers - high quality and reliability from RETSCH

Jaw Crusher technology RETSCH Jaw Crushers are robust and powerful forced-feed crushers. The feed material passes through the no-rebound hopper and enters the crushing chamber. Size reduction …