Impact Crusher Crusherswhen-fighting Crusher

Impact Crusher Rotating. Impact crushers when compared to conventional compression crushers jaw gyratory cone will have a lower installed capital cost per ton of capacity because of the rotating speed of the crusher the operating and maintenance costs and equipment downtime will be higher for the impact crusher.

Impact Crusher - an overview | ScienceDirect …

The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance. The finished product is of cube shape and the tension force and crack is avoided. Compared with hammer crusher, the impact crusher is able to fully utilize the high-speed impact energy of entire rotor.

Impact crushers - high-quality impactors - liming

Impact crushers are named after the method they use in reducing larger blocks of rocks to smaller stone sizes. As the name suggests, an impact crusher accelerates the feed material to high speed and then flings the fast-moving rocks against the walls of the crushing chamber and each other.

Impact Crusher Working Principle

Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them. Impact crushing can be of two variations: gravity and dynamic. An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill). Dynamic impact could be described as material dropping ...

Impact Crusher Working Principle.MP4 - YouTube

29-05-2012 · PF Series Impact Crusher Are Ideal for 1. Primary and secondary for crushing of low abrasion materials; 2. Both stationary and mobile processes; 3. Versatile...

impact crusher crusherswhen - pizzeria …

Sep 21 2018 · Cone crushers are used in secondary and tertiary roles as an alternative to impact crushers when shape is an important requirement but the proportion of fines produced needs to be minimized. Impact crushers. An impact crusher uses mass and velocity to break down feed material. Get Price; impact crusher crusherfeatures

Joyal-Impact Crusher,Impact Crusher For …

The JOYAL Impact Crusher is used for primary, secondary and fine crushing of all kinds of stones and rocks with compressive strength less than 350 MPa such as granite, marble, and limestone. The Impact Crusher is widely used for sand and rock production in the industry of roads, railways, reservoir, electricity power, building materials and so on.

Impact Crusher VS Jaw Crusher:What Are the …

2) Impact crusher can handle various coarse, medium and fine materials (granite, limestone, concrete, etc.) with a particle size not exceeding 500mm and a compressive strength not exceeding 350MPa. Conclusion. Jaw crusher and impact crusher are different in structure, principle, characteristics and …

Used Impact Crushers For Sale | Cleveland Brothers

If you’re thinking of expanding your fleet of equipment with an impact crusher, browse our online inventory and contact Used Equipment SalesCleveland Brothers CB Con-Agg at 866-268-1714 866-956-8733 for more information.

Impact Crusher For Sale & Rental - New & Used …

Impact Crusher for sale & rental | Rock & Dirt. Search from 1000s of listings for new & used Impact Crushers for sale or rental updated daily from 100s of dealers & private sellers.

trio impact crushers - Tuhid

impact crushers portable serial 90452 portable cec secondary impact crusher universal 130150 impactor sn 619 x 151 3 curtains hyrdaulic opener weg 400hp electric motor 1200 rpm ac 6x16 1d. See Details. Impact Crushers For Sale.

How Keestrack Impact Crushers Work - Equip2

An Impact Crusher can reduce an input material to a higher ratio than a standalone Jaw or Cone Crusher; it does this via the use of two aprons suspended over the rotor. Each apron is responsible for 1/2 of the crushing reduction with the 1st apron responsible for the primary crushing operation and 2nd apron fulfilling the secondary crushing; each usually set at 1/3 jumps.

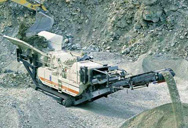

Terex Finlay I-100RS Impact Crusher (Quarry) - …

The NEW Terex® Finlay I-100RS direct drive ø860mm x 860mm (Ø34" x 34") horizontal impact crusher with variable speed gives operators unprecedent¬ed levels of...

Jaw Crusher VS Impact Crusher | Whats The …

Jaw crusher and impact crusher are the main crushing equipments in the ore crushing production line. Jaw crusher is mainly used for the process of high hardness materials, mainly for the coarse crushing of ore, while the impact crusher for the treatment of medium hardness and brittleness stones, mainly for the medium crushing and fine crushing of stones.

What is an Impact Crusher? | Telsmith

Impact crusher machines are available as stationary, track, or mobile units, and can be used in the primary, secondary, or tertiary position in the Producer’s line up. Impact crushers can be subject to high wear and operating costs and high production of fines. View Telsmith Impactors.

Impact Crushers Crushing - android-hubo.de

Impact Crushers Crushing. Crushing impact crushers horizontal impact crusher elrus horizontal shaft impactors our horizontal shaft impacthsi crushing plants are outfitted with prisec crushers s prisec crusher range can be configured to operate in application areas such as quarrying and recycling in either primary or secondary.

Impact Crusher Catalog Pdf - two-do.nl

Impact Crusher Catalog Pdf. Modeling and optimization of a vertical shaft impactor for vertical shaft impact crushers have been used for a long time to reduce the size of operating parameters of the vsi affects the output of the crusherlow of particles, usually done before and …