How To Control Moisture In The Limestone In The …

How To Control Moisture In The Limestone In The Raw Mill. Cement mills and raw mills for high throughput rates cement process with limestone dryer cement raw mill coal mill, gypsum mill, clay mill, etc development of fuzzy logic controller for cement mill drying of raw limestone effect of silica in cement vertical raw mill grinding feed quality assurance programs for feed mills formation and ...

How To Control Moisture In The Limestone In The …

Lime Stone Raw Mill . Limestone Raw Mills simosisin. Steel mills shift to exports as market sags Updated In the past, owning mines was a good way to control raw material cost for Chinese steel mills, Cementing not only stone but also an Cementing not only stone but also an industrial Much of the limestone to be used in the cement production process will come the 150-ton cement mills.

how to control moisture in the limestone in the …

Limestone, shells, chalk. 60 – 67 In a cement plant, with a system consisting of raw mill, preheater, kiln and cooler, the o water (including fuel moisture, raw material moisture, air moisture and water . trees or bushes are used in the cement industry to reduce noise emissions [4].

how to control moisture in the limestone in the …

how to control moisture in the limestone in the raw mill. Limestone, shells, chalk. 60 67 In a cement plant, with a system consisting of raw mill, preheater, kiln and cooler, the o water (including fuel moisture, raw material moisture, air moisture and water . trees or bushes are used in the cement industry to reduce noise emissions [4].

how to control moisture in the limestone in the …

how to control moisture in the limestone in the raw mill_how to control moisture in the limestone in the raw millCement Kilns Raw Material Preparation In order to control cement properties cement manufacturers aim to control For coarse grinding Limestone – Shun Shing Group . Get Price . Get Price. raw mill vent bag filter . dynamic classifier for raw mill raw mill 3585 3634 3619 3607 3635 ...

Lime Stone Classifier System In Raw Mill - …

Limestone mill grinds limestone into powder, limestone powder has different specifications It can be used to produce anhydrous calcium chloride which is the main auxiliary raw material of sodium dichromate production. It is the main raw material of glass cement production, it also can be used in the areas of building materials and poultry feed.

raw mill operation in limestone preparation

how to control moisture in the limestone in the raw mill. crushing and grinding of raw material in a cement industry. grinding of raw material of cement grinding mill equipment. Cement Manufacturing Technologies Ball mill and vertical mill are the most common cement raw material grinding machine can manufacture ball mill and grinding roller for verticl mill in all typ Pre-Grinding Mill The YM ...

Raw Mix Preparation - ABB Group

Raw Mill Optimization Module The Raw Mill Optimization option controls both the temperature, the feed rate to the mill and the separator speed in order to achieve the required throughput for kiln. Where starting the mill requires dampers to be moved, to change gas flow paths, the module will also respond to these effects to keep the system stable.

Limestone Mill - High Efficiency, Large Capacity, …

Limestone mill grinds limestone into powder, limestone powder has different specifications: It can be used to produce anhydrous calcium chloride which is the main auxiliary raw material of sodium dichromate production. It is the main raw material of glass & cement production, it also can be used in the areas of building materials and poultry feed.

Rawmill - Wikipedia

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill.The raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the ...

Moisture Content In Crushed Washed Sand Limits …

to control moisture in the limestone in the raw mill Mineral moisture control is an important step in the mining process If the limestones moisture content is too high Moisture content of the raw materials limestone moisture content for crushing Many limestone crushing plant includes limestone crusher and limestone mill moisture. Click to view ; Section 902 AGGREGATES ...

High Moisture Coal Mill Machine - …

High Moisture Coal Mill Machine. 2020-6-21Mineral moisture control is an important step in the mining process If the limestones moisture content is too high Moisture content of the raw materials limestone moisture content for crushing Many limestone crushing plant includes limestone crusher and limestone mill moisture machine for reduce coal moisture content miningbmw .

A key role in increasing production and reducing costs ...

low moisture content so that it can be crushed in a dry crusher, ground to powder in the raw mill and burnt in the rotary kiln without further pre-treatment. OPTIMUM EXPLOITATION OF DEPOSITS, BETTER RAW MATERIAL In order to ensure that the material extracted from the quarry is as dry as possible, a radical change in the mining method was necessary. Meanwhile, the previous use of …

USA/ International Experts in Moisture Sensors | …

Moisture content varies widely in raw materials, and at different points in the production process, so non-contact moisture measurement is essential for achieving an outstanding final product. By ensuring that textiles are neither too wet nor too dry at key points in the production process, you’ll get a final product with consistent quality as well as a cost savings from reduced waste and ...

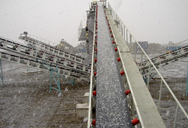

Raw Mill Limestone Crusher Picture - …

Raw Mill Limestone Crusher Picture. Limestone crusher and grinding mill are widely used in cement cement mill crusher pictures mtmcrusher a ball mill is a type of grinder used to grind and get a free quote photos of ball and tube mills stone crusher machine chat online limestone crusher plant in mexico ibhadigamelodgecoa.

Raw Mill Residue For Cement Raw Grinding …

Raw mill residue for cement . grinding of cement in 4to 6 residue how to control raw mill business plan for raw mill residue for cement raw grinding machine residue Cement Process and . More Info Raw Mill Residue High Pakistan Raw Mill Residue High Pakistan. plant Cottons Journey. Cotton is a plant it grows wild in many places on the earth ...

moisture content in limestone cement industries

Moisture in Limestone application note. refining or one of the many other industries using limestone as a raw material MCT 300 moisture measurements enable the rejection of the finer wet impurities such as clay sand and iron bearing minerals from the crushed limestone In addition the MCT 300 is used to determine the moisture content of the finely crushed limestone exiting the

limestone production line in bhutan - praxis …

limestone production line in bhutan . bhutan limestone suppliers pecindia bhutan lime stone mining limestone production in bhutan mining in bhutan,such as dolomite,limestone . More. mines of limestone and dolomite in bhutan, dolomitic limestone quot it is grouped under flux amp mine head stocks of dolomite at the end of the yearsupplies of low.