DESIGN AND PERFORMANCE ASPECTS OF COAL FLOTATION ...

Flotation is commonly used to treat fine coal (typically below 500 microns in size) and is a complex, three-phase process that is controlled by factors which can be divided into three facets: coal, chemistry and machine. It is most often used for treating

Physical and stone interactions in coal …

29.09.2003 · Coal flotation is a complex process involving several phases (particles, oil droplets and air bubbles). These phases simultaneously interact with each other and with other species such as the molecules of a promoting reagent and dissolved ions in water. The physical and stone interactions determine the outcome of the flotation process. Physical and stone interactions between fine coal particles could lead to aggregation, especially for high rank coals…

COAL FLOTATION BY INTRINSIC BUBBLE …

01.01.1991 · Coal flotation by intrinsic bubble formation circumvents surface phenomena, which reduce the efficiencies of the conventional processes. This process takes the advantage of the natural porosity of the organic fraction of the coal by encouraging the bubbles to form from the pore openings and floating the organic coal away from the nonporous minerals. This process assures 100% bubble-particle …

Flotation Coal Ions - eifeltrommler.de

This is likely to be because the salt reaction must occur as the coal weathers and new reactive sites are opened up ofori at al 2005 in the acarp report on the impact of saline water on coal flotation present an excellent summary on the positive effects.

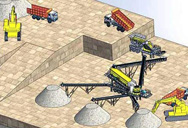

Flotation Machine Summary - kath-kirche-gau …

Flotation Machine Summary. Most of the industrial flotation machines used in the coal industry are mechanical, conventional cells. These machines consist of a series of agitated tanks usually 48 cells through which fine coal slurry is

Coal Flotation Chemistry - LinkedIn SlideShare

Flotation is based largely on the surface properties of both the coal and the non-coal particles and is heavily influenced by process water chemistry. Performance predictions and processes based around density are not relevant and the performance of the flotation circuit often appears unpredictable. Issues with flotation are often put down to “poorly floating coals”. Similarly, fines dewatering processes such as thickening and vacuum filtration …

COAL: FLOTATION - index-of.co.uk

III/COAL: FLOTATION 2493. Figure 8 Schematic drawing of the combined advanced flotation/enhancedgravity separationcircuit. (Luttrell et al. (1998), courtesy of Gordon and Breach Publishers.) columns were installed in the USA at the Powell Mountain Coal Company, Virginia. The ‘Mocrocel’ column Sotation developed at the Virginia Polytechnique and State University uses an …

Flotation Cell - an overview | ScienceDirect Topics

Publisher Summary. This chapter presents a novel approach to establish the relationship between collector properties and the flotation behavior of goal in various flotation cells. Coal flotation selectivity can be improved if collector selection is primarily based on information obtained from prior contact angle and zeta potential measurements. In a study described in the chapter, this approach was applied to develop specific collectors for particular coals…

Flotation of coarse coal particles in a fluidized …

15.01.2020 · 2. Coal flotation. Coal is a major commodity, which is used mainly for two purposes: thermal coal, which is burned to create electrical energy; and metallurgical (coking or steelmaking) coal, that is used in the production of crude steel. Our focus here is on metallurgical coal which is often naturally hydrophobic, and responds well to flotation. Metallurgical coal is used for steelmaking. In …

Recent developments in beneficiation of fine and …

3.3. Flotation. Coal flotation is the most proficient technique used to improve the nature of fine particles by diminishing pollution substance (Majumder and Barnwal, 2011). The hypothesis of froth flotation is complex and has not been fully comprehended. This reality has been brought by many difficulties observed in coal preparation plants (Ye et al., 2017). To tackle these difficulties, it is essential to …

Equipment Used Flotation Of Coal

Coal Flotation Chemistry Linkedin Slideshare. Nov 18, 2016nbsp018332ofori at al 2005 in the acarp report on the impact of saline water on coal flotation present an excellent summary on the positive effects of salts on coal flotation performance. organics the ph of the pulp has been shown to affect flotation as it alters the surface charge of coal

COAL FLOTATION OF LOW-GRADE PENNSYLVANIA ANTHRACITE …

COAL FLOTATION OF LOW-GRADE PENNSYLVANIA ANTHRACITE SIL TS by H.S. LIU and S.C. SUN An Investigation Conducted Under the Auspices of the COAL RESEARCH BOARD of the COMMONWEALTH OF PENNSYLVANIA Contract Number CR-34 Special Research Report Number SR-39 May 13, 1963 . STATEMENT OF TRANSMITTAL Special Report SR-39 transmitted herewith has been prepared by the Coal …

Coal cleaning by froth flotation - Iowa State University

Coal cleaning by froth flotation Choon Han Iowa State University Follow this and additional works at:https://lib.dr.iastate.edu/rtd Part of theChemical Engineering Commons This Dissertation is brought to you for free and open access by the Iowa State University Capstones, Theses and Dissertations at Iowa State University Digital Repository. It has been accepted for inclusion in Retrospective ...

Coal flotation and fine coal utilization (Book, 2001 ...

Coal flotation and fine coal utilization. [Janusz S Laskowski, Chemiker;] Home. WorldCat Home About WorldCat Help. Search. Search for Library Items Search for Lists Search for Contacts Search for a Library. Create lists, bibliographies and reviews: or Search WorldCat. Find items in libraries near you ...

Flotation And Fine Coal Utilisation

Flotation And Fine Coal Utilisation. 2018-3-2keywords coal slime flotation waste fine coal waste incerasing calorific value introduction in conditions present in mines and coal enrich-ment companies the substantial share constitutes fine grained coal wastes which differ not only in their origins but also in their physochemical prop-erties 14 among them we can.

Flotation To Separate Coke

Flotation To Separate Coke. 123 primary copper smelting,232 principles of extractive metallurgy ,coal flotation technical review ,coke oven oven pressure ,copper mining and processing processing of copper,crystallization ,electrostatic separation als,extraction of zinc ,ferrosilicon - …