High-frequency vibrating screens - Wikipedia

15-10-2013 · When designing a high frequency vibrating screen, an optimum point of frequency and amplitude must be chosen, depending on the specific applications. Separation efficiency. The separation efficiency is simply a measure of the amount of material removed by the screen compared to the theoretical amount that should have been removed.

Basic concepts of vibrating screens: What they are, …

30-01-2019 · Basic concepts of vibrating screens: What they are, what they are for and how they work What are vibrating screens and which are its main applications for use. Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening.

Vibrating Screens Market | Industry Growth Report

The segment is not the fastest growing segment when compared to linear motion and elliptical motion vibrating screens. Circular vibrating screen is expected to reach market value of over US$ 1,200 Mn over the course of the forecast period. Some of the key end-use industries that rely on screening using circular motion vibrating screens are ...

Types Of Vibrating Screens | Introduction And …

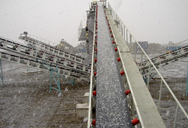

Inclined screen. Vibrating inclined screen is the most popular types of vibrating screens. The screen fix to the tilted frame at an angle of 15 to 30 degrees. The inclined screen is usually designed in a multi-layer structure and can be classified into 2-5 grades. And the screen can be adjusted to provide overall performance and efficiency.

Vibrating Screen Types - Blog - mekaglobal.com

Aggressive vibration is applied within a range of 3600–5000 RPM directly to the screen media, allowing for higher capacity and more efficient sizing when compared with conventional screens. Under the effect of high-frequency vibration, a smaller bed depth is obtained, which allows for stratification and greater screening efficiency.

The main advantages of vibrating screens …

The main advantages of vibrating screens compared to other types of sieves are: 1. Due to the strong movement of the screen surface, the vibrating screen accelerates the speed of the material passing through the sieve hole, so that the sieve has high productivity and screening efficiency (generally ...

Compared with the old vibrating screen, what are …

Asker: Charity Ask date: 9/3/2020 04:06:11PM Question:Compared with the old vibrating screen, what are the advantages of the new vibrating screen? Reply: Dear Charity, 1. Technical aspects Old vibrating screen: adopts the excitation method of shaft

Vibrating Screens - Parker Plant

Parker have been designing and manufacturing vibrating aggregate grading screens for over 50 years and its Rapide range of machines is at the forefront of the need to provide an efficient screen with features ensure good results and effectiveness in the application required.

The advantages of the tumbler screen compared …

The advantages of the tumbler screen compared with the three-dimensional vibrating screen. The tumbler screen is a new type of vibrating sieve newly developed in recent years. It aims at the drowning products extended under the environment of low penetration rate, low production efficiency and limited space in the site.

CHYI MEANG MACHINERY CO.,LTD.-crusher …

Vibrating Screen. CMC VS-E Series Horizontal Screen applied three -shaft vibrating mechanism to have an oval stroke motion. Screen efficiency is much better compared to traditional straight and circle stroke. Special mechanism with no bending and no heat stretch on shaft, so service life of bearing is extremely long. more

The advantages of the tumbler screen compared …

The advantages of the tumbler screen compared with the three-dimensional vibrating screen. los tumbler screen is a new type of vibrating sieve newly developed in recent years. It aims at the drowning products extended under the environment of low penetration rate, ,

Vibrating Screen - dorpenstage.nl

Vibrating Screen is of high vibration intensity. Under the same specifications, it has larger processing capacity and higher screening efficiency compared to traditional screens. It is particularly applicable to heavy type, middle type and fine screening operations, and it is the ideal screening equipment for primary crushing, secondary crushing and finished materials.

Vibrating Screen Design Parameters

Table of ContentsModel DesignOperating and Control StrategiesResults An analysis of screen design options on the operating efficiency of secondary crushing plants has been conducted using a dynamic computer model. The model allows for the simulation of a wide variety of crushing circuits and can be run on either a microcomputer (IBM PC/XT) or a large time-sharing mainframe computer. Size ...

Screening Theory and Practice - Triple/S Dynamics

The Horizontal Vibrating Screen: 840 rpm , 1/2” stroke at 45°. Each has a .063” dia. wire screen with 1/8” clear opening, moving under a particle travelling at an assumed 20 fpm, for A, 40 fpm for B., 80 fpm for C, and 60 fpm for D. Omitting details

Vibrating Screen Havre Compared Poker

Vibrating Screen Havre Compared Poker Vibrating Screen Technical Turkey Protable Plant We are a large-scale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral …